Choosing Pre-Insulated Ductwork Helps to Save Space

The Kingspan KoolDuct System Maximizes Space Efficiency

Maximizing space efficiency in the construction of new buildings or remodeling of pre-existing buildings is an important aspect that engineers have to consider when designing a building. This is especially true for buildings where there is already less space per occupant available (e.g. healthcare facilities and schools).

Typically, available space in a building is calculated in terms of “building floor area.” However, volume should also be taken into consideration when determining available space. Most commercial and institutional buildings have to accommodate necessary services (e.g. IT & communications, fire suppression, HVAC systems, electrical, structural, etc.) that are required for the businesses or institutions within. In order to meet the requirements for these buildings, space efficiency should be a top item when considering how to design a particular building.

The Kingspan KoolDuct System is pre-insulated phenolic ductwork designed to minimize the amount of space required to be dedicated for ductwork in any building by eliminating the extra space needed to manually install a layer of insulation around the ductwork.

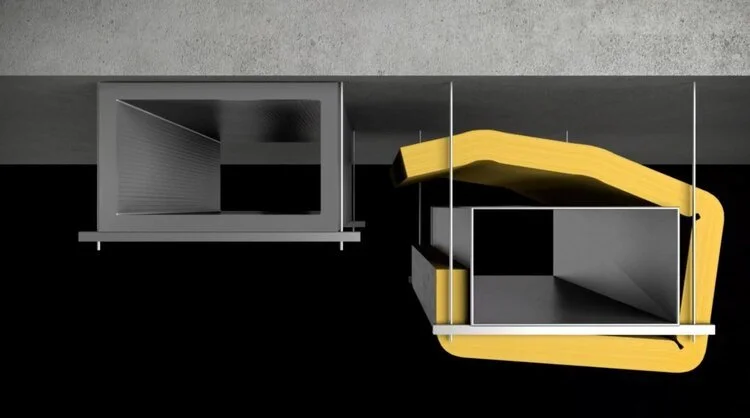

KoolDuct (left) can be mounted flush to ceiling, whereas traditional ductwork (right) needs 6-8” of room to apply insulation

The Kingspan KoolDuct System defies the normal space requirements by being pre-insulated. Because it is pre-insulated, KoolDuct has the ability to be constructed with flush joints between sections. This allows KoolDuct to be installed even between members of steel roof trusses or other structural features. This type of installation allows for the maximization of space that can then be dedicated to other services, or just reduce the amount of service space altogether. The use of this product is particularly advantageous with main riser ductwork, and if used early on in the design process, could lead to an increase in usable floor space.

An independent consulting company, Rider Levett Bucknall, conducted research on the Kingspan KoolDuct System and found that amongst the most frequent types of responses were those regarding the space efficiency of KoolDuct. To further their research, Rider Levitt Bucknall completed an independent cost analysis of the benefits of the product in a space-saving facility. The results indicated that the use of KoolDuct could reduce 1-2% in overall construction cost for that particular project. This reduced cost stems from the reduced structure, internal wall, wall finishing and cladding required.

Considering the benefits of the Kingspan KoolDuct System, this should be the HVAC ductwork product used when designing a building that maximizes on space efficiency.

For indoor applications such as mechanical rooms, shafts and other high traffic areas where increased durability is desired, the Pro-R duct system should be considered. Pro-R utilizes the proven KoolDuct system but goes a step further by integrating KoolDuct with a tough and durable metal exterior. Pro-R was designed to withstand harsh weather in outdoor applications and serves as an excellent choice for indoor applications as well.